Read This JCB 8250 Fastrac Operator’s Manual carefully to learn how to operate and service your machine correctly. Failure to do so could result in personal injury or equipment damage.

The operating instructions are to be read and used carefully by all persons who carry out work with or on the machine before putting the machine into service for the first time and later, at regular intervals. The operating instructions allow the machine operator to familiarize himself with the machine more easily and prevent malfunctions occurring due to improper operation.

– increases reliability in use.

– extends the service life of your machine.

– reduces repair costs and downtime.

These operating and maintenance instructions contain all the information required for operating and maintaining your machine.

Models Covered:

JCB 8250 Fastrac

from serial number 1138000

Manual Contents:

Safety Notices

Important Information

The Operator Manual

Safety Warnings

Introduction

About this Manual

Machine Models and Serial Numbers

Using this Manual

Units of Measurement

Left Side, Right Side

Cross References

Using the Machine

Optional Equipment

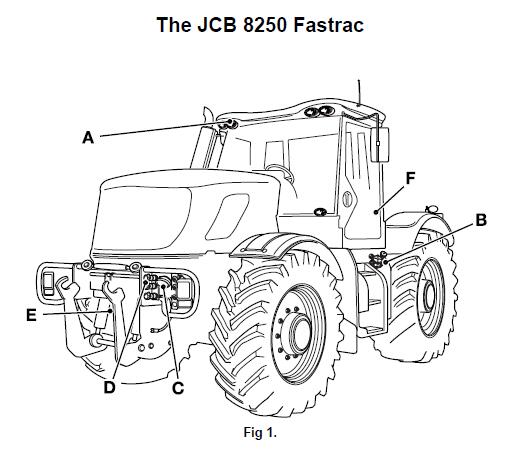

The JCB 8250 Fastrac

Safety First

Safety – Yours and Others

Safety Check List

General Safety

Operating Safety

Maintenance Safety

Safety Decals

Safety Decal Recognition

Identifying your Machine

Serial Number Plate

Operation

Introduction

Before Entering the Cab

Entering and Leaving the Cab – Doors and Windows

Adjustable Steps

Opening and Closing the Doors

Opening and Closing the Windows

Cab Layout

Seat Controls

Standard Suspension Seat

Heated Seat (Optional)

Seat Belts

Introduction

Fasten the Seat Belt

Check the Seat Belt is Operating Correctly

Release the Seat Belt

Drive Controls, Switches and Instruments

Steering Column Multi-Purpose Switch

Front Console Switches

Side Console Controls

Area Cut-out Socket

Limp Home and Diagnostic Switch and Socket

Starter Switch

Steering Column Adjustment

Instruments

Warnings (Audible/Visual)

Warnings (Visual only)

EMS Programming Mode Levels 0 and 1

Wheel Slip

Air Conditioning and Heater Controls

Cab Interior Light

Auxiliary Sockets

Safety Equipment

Transport Locks

Before Starting the Engine

Starting the Engine

Normal Starting

Cold Starting

Preparing for Travel

Before Travelling on Public Roads

Getting the Machine Moving

General Precautions

Continuously Variable Transmission (CVT)

Anti-lock Braking System (ABS)

Testing the Park Brake

Parking the Machine

Parking on an Incline

Working with your Machine

Using the Machine and Site Safety

Safety Must Come First

Four Wheel Drive and Differential Lock

Rear 3-point Linkage Control

Rear 3-point Linkage Mechanical Connections and Adjustment

Front 3-point Linkage Control (Optional)

Front 3-point Linkage (optional)

External Hydraulics

Quick Release Couplings

Drawbars and Hitches

Ladder Hitches

Connecting Trailer Air Brakes

Connecting Trailer Hydraulic Brakes

Independent Power Take-off (PTO)

Touch Screen Settings

Operating in Low and High Temperatures.

Low Temperatures

High Temperatures

Moving a Disabled Machine

General

Limp Home Mode

Preparation for Towing

Transporting the Machine

Routine Maintenance

Service Requirements

Introduction

Owner/Operator Support

Service/Maintenance Agreements

Initial Service and Inspection (100 Hours)

Obtaining Replacement Parts

Health and Safety

Lubricants

Battery

First Aid – Electrolyte

Service Schedules

How to Use the Service Schedules

Service Schedule Tables

Fluids, Lubricants and Capacities

Coolant Mixtures

Cleaning the Machine

Checking for Damage

Seats and Seat Belts

Seats

Checking the Seat Belt Condition and Security

Checking the ROPS Structure

Bonnet

Opening the Bonnet

Closing the Bonnet

Greasing

General Information

Propshafts and Rear PTO Drive Shaft

Front 3-Point Linkage (Optional)

Front Axle Steering Swivels

Steering Column Universal Joints

Rear Suspension Cylinder Pivots

Hydraulic Lift and 3-Point Linkage

Pick-up Hitch

Automatic Trailer Coupling (if fitted)

Air Conditioning and Heater

Air Conditioning Filters

Cleaning the Heater Filter

Adjusting the Compressor Belt

Brakes

Checking the Foot Brake Fluid Level

Checking the Trailer Air Tank

Checking the Air Tank Warning Lights

Checking and Renewing Foot Brake Pads

Checking the Park Brake Pads

Electrical System

Battery

Jump-starting the Engine

Fuses

Relay Identification

Checking the Beam Alignment

Engine

Changing the Air Filter Elements

Checking the Oil Level

Changing the Oil and Filter

Checking the Crankcase Breather Tube

Cooling System

Checking the Coolant Level

Changing the Coolant Filter

Draining and Refilling the Coolant

Cleaning the Radiator and Coolers

Fan Belt

Fuel System

Types of Fuel

Filling the Tank

Draining the Fuel Filter

Changing the Fuel Filter Elements

Hydraulic System

Checking the Fluid Level

Changing the Filter Element

Emptying the Hydraulic Coupling Drain Reservoirs

Transmission

Checking the Transmission Oil Level

Changing the Transmission Oil Filter

Changing the Transmission Oil and Strainer

Checking the Clutch Fluid Level

Axles

Front Axle

Rear Axle and PTO

Tyres and Wheels

General

Wheel and Tyre Replacement

Checking Wheel Nut Torques

Adjustable Track Width

Tyre Inflation

Checking and Adjusting the Front Wheel Alignment

Fender Adjustment

Power Take-off (PTO)

Front PTO

Rear PTO

Windscreen Washer

Checking Fluid Level

Automatic Trailer Coupling (Optional)

Checking for Wear

Specification

Static Dimensions

Weights and Loads

Unladen Weights

Load Capacities

Laden Weights

Tyres

General

Tyre Pressures, Speeds and Loads

Travel Speeds

General Information

Warranty

Machine Service Record Sheet

Registration Information

And More………

============================

File Format: PDF

Compatible: All Versions of Windows & Mac ,Android

Language: English

Total Pages: 255

This manual is INSTANT DOWNLOAD. You can save time and money by purchasing this manual, which you can browse on your electronic products, or print out for reference.

We not only provide quality manuals, but we will also Provide excellent after-sales service, Customer Satisfaction Guaranteed! we offer free replenishment of any manual that we sold to you. If you lost or not found your manual, And any questions, please contact me.

support email: manualservicerepair@outlook.com

Thank you for coming and reading.